Cleanroom

The function of a cleanroom is to keep the concentration of particles in the air low.

Cleanroom ensures product quality

State-of-the-art research, development and manufacturing processes increasingly require environmental conditions in which the airborne particle concentration should not exceed specific limits.

Definition: What is a cleanroom?

"Room with a defined concentration of airborne particles, designed and used in a way that the number of particles introduced into the room or originating and being deposited in the room is as small as possible, and in which other cleanliness-relevant parameters such as temperature, humidity and pressure can be controlled as required.” (VDI 2083-1)

The incoming air is processed by means of HEPA and ULPA filters to protect particularly sensitive products in research, technology, industry, and pharmaceutical applications against harmful environmental influences. To this end, also the staff in the clean room must comply with rules of conduct that dictate defined protective clothing.

Cleanrooms can cover areas of various sizes. From individual equipment to complete production facilities. The appropriate solution always depends on the requirements of contamination control.

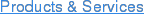

The probably most important requirement is the airborne particulate cleanliness class. This is classified by specifying the maximum permitted number of airborne particles and divided into 9 ISO classes:

Source: DIN EN ISO 14644-1:2016-06

After the ISO class of the clean room has been specified, the type of air flow around the product must be considered.

Relevant flow principles in the cleanroom

1. Turbulent dilution flow: “non-unidirectional airflow. Air distribution during which primary air entering the cleanroom or clean area is mixed with the room air by means of induction.” (ISO 14644-1 - 2016-06) The filtered clean air is introduced into the clean room with a swirling effect and generates an increasing dilution of the particle concentration. With this flow principle, the staff’s behaviour according to clean room conditions is particularly important in order to ensure the required airborne particulate cleanliness class.

2. Low-turbulence displacement flow: “unidirectional airflow, regulated airflow with uniform speed across the entire cross-section of a cleanroom or clean area, which is regarded as parallel airflow.” (DIN EN ISO 14644-1 - 2016-06) This is also called “laminar flow” and requires a low-turbulence inflow. In this procedure, the air escapes on the opposite side, normally consisting of a perforated double floor. From there, it returns into the recirculation device where it is filtered again. The low-turbulence displacement flow is particularly suitable for sensitive work areas.

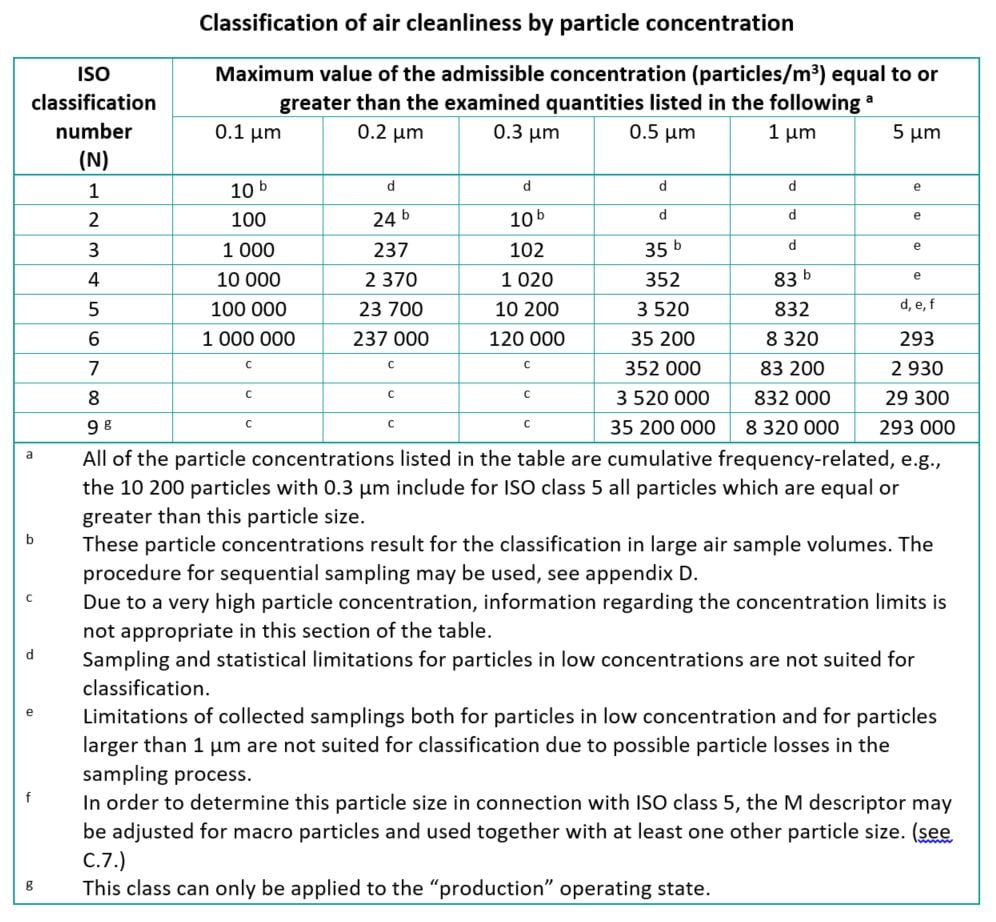

Fan-filter modules (FFM) consist of three main components:

Basic structure of cleanrooms

Each cleanroom environment has different installation conditions and requirements. Depending on those, the solution can feature solid wall elements (hardwall) or foil curtains (softwall) and equipment as well as come in different sizes.

Softwall cabins

Structure

PVC curtains shield the local clean air area against environmental influences. Several fan-filter-modules ensure the supply with "pure" air. The exhaust air can easily escape the cleanroom under the curtains.

Advantages

- individual planning and installation

- easy integration of work surfaces shelves, wet stations, separately enclosed inspection workstations as well as airlocks for people and material

- adaption possibility for expansion of the production area

- additional fan-filter-modules can be installed easily

Hardwall cabins

Structure

Using a hardwall cabin, you can quickly create a clean environment for a specific process. Standardized segments allow simple setup of different cabin sizes.

Advantages

- available in all purity classes

- suitable for use in production areas with very narrow climate tolerances

- precise examination of products or production processes possible

Advantages of modular cleanroom systems

- individual planning and installation

- easy integration of work surfaces, shelves, wet work stations, separately enclosed inspection workstations as well as airlocks for people and material

- adaption possibility for expansion of the production area

- additional fan-filter-modules can be installed easily

Advantages of clean working zones

- the principle of the modular cleanroom can be transferred to work benches, individual cabins and minienvironments

- individual modules are easy to connect and tailor to customer requirements

- systematic use of the available space

- provides an improvement in the purity class also outside the work surfaces

Cleanroom technology in its entirety has developed enormously in the economic field. There must be an appropriate ratio of quality and costs. The comparison shows that a standard cleanroom is not always necessary.

The modular cleanroom systems prove to be an appropriate solution especially for small and medium-sized enterprises as they ensure a high degree of flexibility and the ability to modify production areas. The transition between modular cleanroom systems and clean work zones is fluent.

Flexible cleanroom solutions

A cleanroom solution is vital for applications in research, development and production which must take place in ultra-low particle environments. However, the best option is not always a standard cleanroom. Cost-efficiency, above all, is an important factor in this context. A rental cleanroom, for instance, could be a valid solution for small and medium-sized enterprises to avoid the high investment in a standard cleanroom. Moreover, rental cleanrooms offer a high degree of flexibility to provide short-term solutions for order peaks, measuring and testing tasks.

Requirements on mobile rental cleanrooms

- easy assembly and disassembly

- can be adapted flexibly

- meets highest expectations

Find out more in our blog post: “Benefits and application areas of mobile cleanrooms”!

Grey room

The term grey room is used for spatially separate areas whose air purity is better than that of the surrounding spaces, but which do not necessarily offer cleanroom quality. In order to achieve the required cleanliness, special clean air modules have been developed. Thanks to a fine dust filter, coarse particles are filtered from the ambient air. These modules achieve a higher airflow rate and adequate air filtration.

Rental Cleanroom

A rental cleanroom is perfect for temporary cleanroom requirements. Installed on-site in little time, it provides the right process conditions for demanding production, measuring and testing tasks as well as for commissioning of machines, their cleaning and packaging of products.

This video shows how simple, fast and easy it is to set up a rental cleanroom:

Inspection cabin

The rental cabin is suitable for your short-term, space-saving use and tasks with light-tight requirements. It can be used to quickly create a clean environment – without long set-up and dismantling times and high acquisition costs. Inspection tasks can be carried out thanks to the black surfaces and black fan-filter modules.

Clean Tent / Cleanroom Tent

With a portable cleanroom tent (CleanTent), you can quickly and easily create a short-term cleanroom environment, for example, for service, repair and maintenance work on sensitive machines and products. The inside of the COLANDIS CleanTent is supplied with pure air by means of two fan-filter modules and can therefore reach air purity class ISO 5 in the working area (approx. 1.2 x 0.6 m²).

Cleanroom summary

Each cleanroom environment has different installation conditions and requirements. You must find out which solution is appropriate for the described process. The solution can be a hardwall or softwall cleanroom or also a special solution. However, what is important for product quality is not only the cleanroom itself but also the behaviour of staff, professional cleaning and continuous measurements as well as a successful qualification and re-qualification of the cleanroom.

Cleanrooms in production

The goal of zero-defects production in suitably clean production can only be achieved when the entire process chain is considered. Part cleaning and cleaning of complete assemblies and machines also plays an enormous role in this context. Over the last few years, many industries have increasingly been harnessing the positive influence of cleanrooms on product quality. The automotive industry and precision engineering, for instance, use cleanroom conditions for more and more process steps.

Suitably clean production does not exclusively mean production under cleanroom conditions. Of course, there is the question of cleanroom or grey room to increase product quality at every stage of the process. However, frequently, already consistently defined processes are a first step to protect the quality of products and save costs.

- Please see our white paper “Process development in cleanroom conditions” for more information on this topic!

Relevant sectors

- semiconductor technology

- laser technology (go to blog post)

- optics (go to blog post)

- aerospace

- nanotechnology

- food industry

- plastic injection moulding (go to white paper)

Working in a cleanroom

In order to meet the special requirements placed on cleanrooms or on special solutions such as minienvironments, all factors threatening cleanliness must be taken into account. Each individual element within the clean environment can contribute to the contamination of the complete system. In addition to the processes and machines in the room, the human factor, or staff, in particular pose major risks of contamination.

Working in a cleanroom

In order to meet the special requirements placed on cleanrooms or on special solutions such as minienvironments, all factors threatening cleanliness must be taken into account. Each individual element within the clean environment can contribute to the contamination of the complete system.

In addition to the processes and machines in the room, the human factor, or staff, in particular pose major risks of contamination.

-

Food and drink in a cleanroom

- Bringing food and beverages to the clean workplace is prohibited.

- A water dispenser should be available for staff in the personnel lock.

-

Diseases

- Never cough or sneeze in the direction of the critical work area.

- A sick employee should be replaced by another employee for the duration of the infection.

- If an employee is permanently unfit for working in a cleanroom, he/she should be transferred in the company.

-

Personal traffic in the cleanroom

- Only trained staff should work in the cleanroom.

- Only the required minimum of staff should be present at the clean workplace.

- If possible, inspection and maintenance work should be conducted from the outside.

-

Personal

- Bringing personal items (e.g., jewellery, tobacco products, cosmetics) to the clean workplace is prohibited.

- Using make-up such as powder, lipstick, etc. is to be avoided.

The essential behaviour rules in cleanrooms

Employees in the clean environment not only need to wear special garments but should also have been trained appropriately in dealing with processes and work steps in the clean environment. Rules for behaviour in the cleanroom are different in each company and must be aligned with the process and product quality. Hence, dress codes are not universally valid but must be checked and enforced.

Our view

"In summary, you can thus say that clean environments are gaining importance in more and more areas. However, you must always consider the complete process chain. In the end, a complete cleanroom is not always necessary. Frequently, it is sufficient to resort to smaller, local solutions of cleanroom technology because "the best cleanroom is the one, that you don't need." (quote by Joachim Ludwig, COLANDIS Gmbh)