Quickly and easily create a stable, clean environment to protect your processes

A clean environment for your process can be created quickly and easily with a hardwall cabin. Since this can vary in size, this type of cabin is often referred to as a cleanroom. By combining standardized segments, different cabin sizes are available. Due to this modularity, a hardwall cabin can also be adapted to your requirements and ideas at any time. The size can be easily adjusted due to increasing demand.

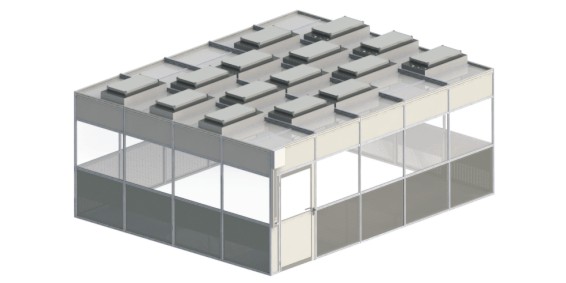

A clean environment can be created quickly with such a cabin. Modular segments enable simple construction and expansion with increasing purity requirements for your processes. A hardwall cabin can be constructed in various air cleanliness classes. The cleaned air is inserted into the cabin by the fan-filter-modules located on the ceiling. Depending on requirements and installation conditions, this can also vary and the modules are mounted laterally for a horizontal air flow.

Hardwall cabins can be built in different shapes, widths and heights, individually adapted to your requirements.

The construction of such a cabin can be made of aluminium profile or monoblock wall systems. The wall elements can be made of different materials such as PVC, PMMA or glass. Each material has its advantages and disadvantages, which should be considered in advance before the construction of such a cleanroom and under consideration of the requirements. In close contact with you, we can find the right material and the best solution for you.

Depending on the required air cleanliness class, an additional air lock has to be installed. The material is inserted through a material lock for the clean environment, which can be designed actively or passively. In the personnel lock, the personnel can dress accordingly for the clean environment.

A cleanroom can be built in various air cleanliness classes. Cleanrooms with air purity class ISO 1 can be reached with hardwall solutions. It is particularly suitable for use in production areas with very narrow climate tolerances. In such a clean environment, it is possible to examine products or production processes. Entire processes can run under clean conditions and thus protect the product from damaging particles.

Clean environments are becoming necessary in more and more areas of industry. For example, cleanrooms and cabin solutions have become indispensable in the food, optics, automotive and semiconductor industries.

Together with you, we will find the right solution to protect your process optimally from harmful particles.

Take advantage of the capabilities of our networks!