Reasons for regular cleanroom maintenance

Scheduled and preventative maintenance of cleanroom technology systems and equipment is a sensible consideration, especially for economic reasons....

Although often declared as a secondary process in cleanroom technology, the storage and transport of materials and products are of enormous importance in the production process. Optimum storage and transport conditions are essential, especially for all companies that work with high-precision and sensitive products and require cleanroom conditions for their use or processing.

Whether particle-free components in optics, semiconductor technology, laser technology or automotive: each of these sensitive parts requires transport that has to fulfil very strict requirements in terms of storage conditions. Due to these increased conditions, the requirements of companies and suppliers in the high-tech industry, where sensors and other very sensitive components are used, are also increasing.

It should be realised that critical components can be destroyed after a very short time as soon as they are exposed to normal environmental air conditions. During long-term storage, harmful particles can also settle on the surfaces inside cleanrooms or sensitive materials can be damaged by humidity and oxygen in the air (contamination is a function of time).

It should be realised that critical components can be destroyed after a very short time as soon as they are exposed to normal environmental air conditions. During long-term storage, harmful particles can also settle on the surfaces inside cleanrooms or sensitive materials can be damaged by humidity and oxygen in the air (contamination is a function of time).

By using storage systems, the storage of sensitive products and materials under cleanroom conditions can be guaranteed. Fan-Filter-Modules ensure a high level of particulate cleanliness inside the storage system.

If oxygen or humidity are damaging to devices, technical components or materials, storage in a nitrogen-purged atmosphere is an option. Due to the physical properties of nitrogen, dry and low-oxygen storage can be guaranteed. This creates optimum environmental conditions for sensitive parts and components.

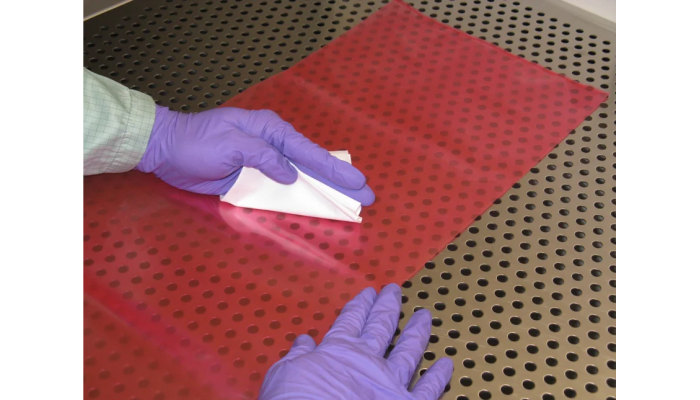

All parts and products leave the storage at some point. It happens all too often that products were cleaned and stored in cleanroom conditions and are packed in uncleaned packaging materials, which leads to entire effort required in advance for cleanroom-compliant production being reduced to the point of ridiculousness. Sufficiently clean packaging is available on the market or you can fall back on previously used packaging that has been cleaned using a qualified cleaning method.

Another critical point during transport under cleanroom conditions is also frequently recognised: Foil packaging is merely folded shut and not sealed. This leads to the packaging ‘breathing’ due to transport movements and fluctuations in air pressure, resulting in gradual contamination. This is not a problem with sealed packaging, as long as it is handled in accordance with the introduction regulations before the products are unpacked (cutting open the plastic film) in order to prevent contamination being carried onto the product from the outer packaging.

Protection against product contamination is also required for in-house transport through cleanrooms with lower particle purity of the air. With clean air-purged transport trolleys, challenging and sensitive products can be transported under cleanroom conditions. The ultra-pure air is supplied using the recirculation principle via a fan-filter-unit in combination with backflow areas. Such transport trolleys can also be used to transport contamination-sensitive products between cleanrooms while maintaining a high level of cleanliness.

The entire process chain must always be considered for zero-defect production with cleanliness-compliant manufacturing. Packaging, storage and transport in line with purity requirements play just an important role as the rest of the process chain. However, the entire process chain is too often neglected and previous work steps lose their effect and the product loses its quality.

Find out what you need to pay attention to when organising processes under cleanroom conditions in our free whitepaper – from component cleaning to the finished product. Simply click on the button and download the whitepaper ‘Process design under cleanroom conditions’.

Scheduled and preventative maintenance of cleanroom technology systems and equipment is a sensible consideration, especially for economic reasons....

For some years, the term ‘grey room’ has been used in customer discussions and specialist articles. But how exactly is a ‘grey room’ defined? And how...

In order to properly specify the cleanliness of a machine in advance, it is necessary to analyse the entire process chain from the production of...