Fan-Filter-Modules (FFU)

Fan-filter-Modules and clean air modules are used to supply clean air. This can be a large cleanroom, a minienvironment, a workplace or a clean/...

The semiconductor industry in particular relies on a clean production environment. This applies not only to particulate contamination but also to molecular contamination. The machines and materials used in the cleanroom play a decisive role in maintaining the respective cleanliness classes and therefore product quality.

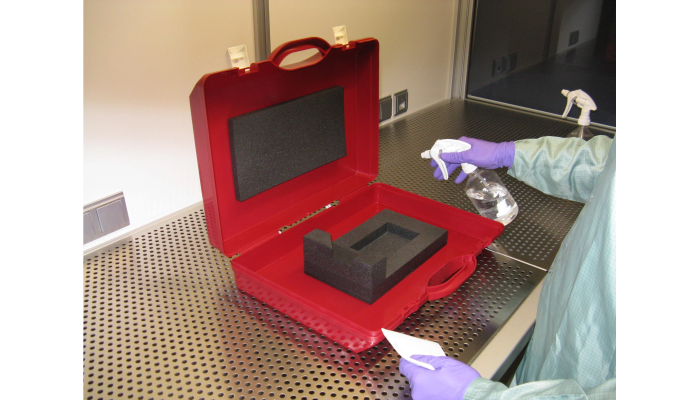

Regardless of the industry, the following generally applies: materials used in cleanrooms should be smooth and easy to clean. They should also be resistant to solvents and low in outgassing. Of course, they should also fulfil design requirements such as strength, functionality etc. In practice, stainless steel, anodised aluminium and glass are mostly used.

The following overview shows examples of materials that are mainly used in technical industries (e.g. semiconductor technology).

The following graphic shows the different requirements in different industries. Specifically, materials used in the semiconductor industry are compared with materials used in the pharmaceutical industry.

Sometimes the design requires the use of materials that do not meet the required specifications. Suitable measurements must be taken to avoid any risk to the process or the product. Suction systems, appropriate air ducts or enclosures can be suitable examples of such measures.

Sometimes the design requires the use of materials that do not meet the required specifications. Suitable measurements must be taken to avoid any risk to the process or the product. Suction systems, appropriate air ducts or enclosures can be suitable examples of such measures.

In the case of a printer, for example, this can be ensured by means of a printer enclosure in a cleanroom.

Due to different requirements and processes in industries and companies, there is no generally applicable procedure for assessing suitable materials in cleanrooms. Not even in the semiconductor industry.

Not sure which materials are best for you? Which will serve your purpose and are most cost-effective? Feel free to contact us – we will be happy to analyse your circumstances and give advises for the best individual solution.

Fan-filter-Modules and clean air modules are used to supply clean air. This can be a large cleanroom, a minienvironment, a workplace or a clean/...

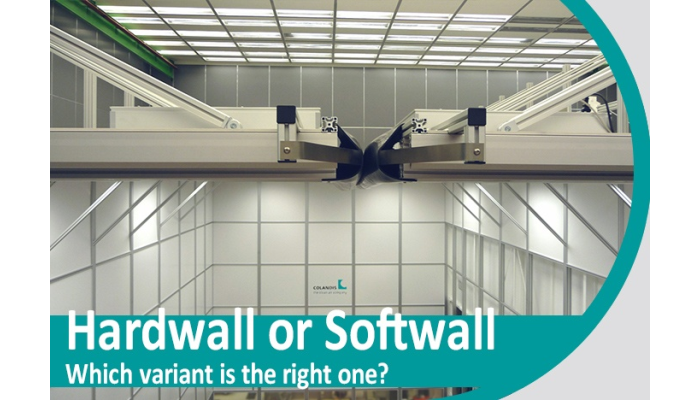

The design and planning of a cleanroom depends first and foremost on the requirements placed on it. In some cases, a cleanroom is sufficient, but...

Regular cleaning of a cleanroom is widely recognised by cleanroom users as an important factor in maintaining the required air cleanliness class in...